Dans le monde des matériaux de haute performance, solutions personnalisées en carbure se distinguent par leur durabilité, leur adaptabilité et leurs propriétés mécaniques supérieures. Que ce soit dans l'aérospatiale, l'automobile, l'exploitation minière ou toute autre industrie exigeante, les composants en carbure deviennent souvent l'épine dorsale de l'ingénierie de précision. Dans ce guide, nous allons plonger dans le monde des solutions personnalisées en carbure - ce qu'elles sont, comment elles sont fabriquées et pourquoi elles sont importantes. Découvrons la science et l'art d'adapter le carbure à des besoins spécifiques.

Que sont les solutions personnalisées en carbure ?

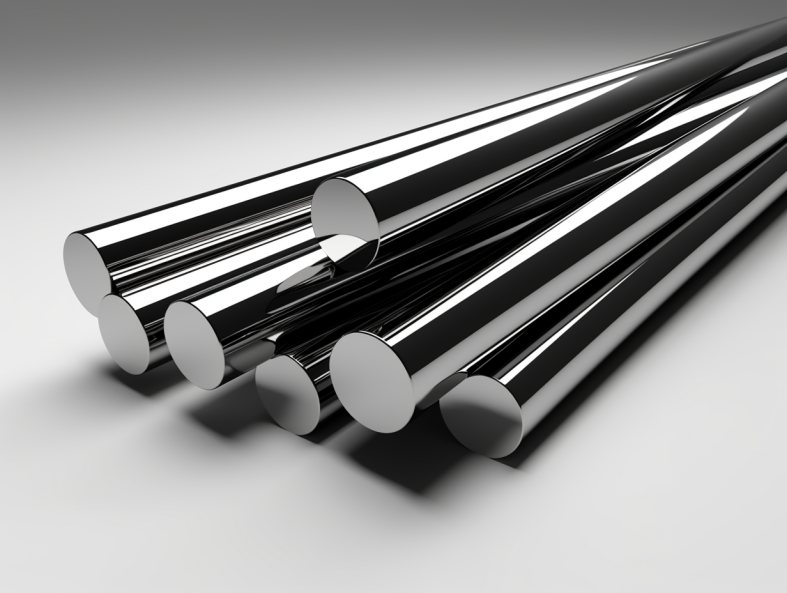

Les solutions personnalisées en carbure sont des composants techniques sur mesure fabriqués à partir de poudres de carbure de tungstène (WC) mélangées à des liants tels que le cobalt ou le nickel. Ces matériaux sont très appréciés pour leur dureté, leur résistance à l'usure et leur solidité exceptionnelles. Qu'est-ce qui les rend "personnalisés" ? La possibilité de modifier les propriétés telles que la ténacité, la taille des grains ou le pourcentage de liant pour les adapter à des applications spécifiques.

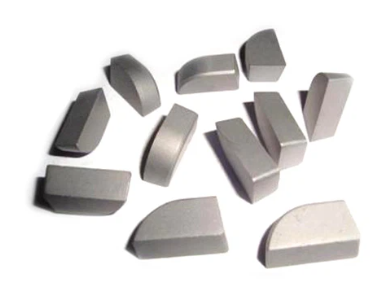

Types de solutions personnalisées en carbure

| Type | Description | Applications clés |

|---|---|---|

| Carbure de tungstène-Cobalt | Combine le carbure de tungstène et le cobalt pour une résistance et une ténacité modérée. | Outils miniers, outils de coupe |

| Carbure de tungstène-Nickel | Résistant à la corrosion ; excellent dans les environnements difficiles. | Traitement chimique, industries pétrolières et gazières |

| Carbure ultrafin | Les grains de très petite taille garantissent une grande précision et une résistance extrême à l'usure. | Microperceuses, électronique |

| Carbure renforcé | Comprend des additifs tels que le carbure de titane pour une performance accrue. | Usinage à grande vitesse |

| Carbure résistant à la corrosion | Utilise des liants à base de nickel ou de chrome pour résister à l'oxydation et aux attaques chimiques. | Environnements marins, produits chimiques agressifs |

| Carbure à usage intensif | Conçu pour une ténacité et une résistance à la rupture maximales. | Matériel d'exploitation minière, de concassage et de terrassement |

| Hybrides en carbure de céramique | Combinaison de céramiques pour des solutions légères mais résistantes. | Aérospatiale, robotique avancée |

| Carbure thermiquement stable | Conçu pour les environnements à haute température. | Moteurs à réaction, systèmes de gestion thermique |

| Carbure recyclé | Option durable utilisant des matériaux de récupération sans compromettre la qualité. | Usage industriel général |

| Carbure nanostructuré | Technologie avancée avec des grains à l'échelle nanométrique pour une précision extrême et des propriétés de résistance à l'usure. | Instruments médicaux spécialisés, appareils de haute technologie |

Analyse des matières premières et de la composition

Ingrédients de base Solutions personnalisées en carbure

- Carbure de tungstène (WC): L'ingrédient principal, qui offre une dureté et une résistance à l'usure inégalées.

- Métaux liants (cobalt, nickel): Améliore la ténacité et lie les grains de carbure entre eux.

- Additifs: De petites quantités de matériaux tels que le carbure de titane (TiC) ou le carbure de tantale (TaC) améliorent la stabilité thermique ou la résistance à l'usure.

Importance de la pureté des matériaux

La qualité des composants en carbure commence par la pureté des poudres brutes. Les impuretés peuvent entraîner une fragilité, des performances irrégulières ou une durée de vie réduite. Des techniques avancées d'analyse des matériaux, notamment la diffraction des rayons X (XRD) et la microscopie électronique, garantissent la composition précise des poudres.

Applications des solutions personnalisées en carbure

| L'industrie | Applications courantes |

|---|---|

| Exploitation minière | Forets, outils de coupe, composants résistants à l'usure. |

| Aérospatiale | Pièces résistantes à la chaleur, hybrides légers pour moteurs. |

| Pétrole et gaz | Bagues d'étanchéité, valves résistantes à la corrosion, outils de forage directionnel. |

| Médical | Outils chirurgicaux, forets dentaires et fraises de précision. |

| Automobile | Engrenages résistants à l'usure, outils d'usinage à grande vitesse, systèmes d'injection de carburant. |

| La construction | Outils de broyage de roches, marteaux et burins. |

| Fabrication industrielle | Matrices, poinçons et lames de coupe pour les lignes de production. |

Déroulement du processus de production

- Préparation de la poudre: Mélange de poudres de carbure de tungstène avec des liants et des additifs.

- Mélange et broyage: Distribution homogène des ingrédients pour obtenir des propriétés constantes.

- Appuyer sur: Compactage dans les formes souhaitées à l'aide de presses isostatiques ou uniaxiales.

- Frittage: Chauffage dans une atmosphère contrôlée pour densifier le matériau et améliorer ses propriétés.

- Finition: Procédés de rectification, de rodage et de revêtement pour obtenir des dimensions et des surfaces précises.

Propriétés matérielles des Solutions personnalisées en carbure

| Propriété | Plage de valeurs | Impact |

|---|---|---|

| Dureté (HV) | 800-2000 | Détermine la résistance à l'usure et à l'abrasion. |

| Résistance à la rupture (MPa-m1/2) | 6-15 | Des valeurs plus élevées signifient une meilleure résistance à la fissuration. |

| Densité (g/cm³) | 13.5-15.5 | Affecte le poids et la stabilité. |

| Conductivité thermique (W/m-K) | 80-120 | Efficacité dans la dissipation de la chaleur. |

| Module d'élasticité (GPa) | 500-700 | Indique la rigidité et la résistance à la déformation. |

Composition, propriétés et caractéristiques

| Composition | Propriétés | Caractéristiques |

|---|---|---|

| WC + 6% Co | Dureté élevée, ténacité moyenne. | Idéal pour les outils de coupe. |

| WC + 12% Co | Ténacité améliorée, dureté légèrement inférieure. | Convient aux outils d'exploitation minière. |

| WC + 10% Ni | Résistant à la corrosion et à l'usure. | Idéal pour les applications chimiques. |

| WC + TiC + Co | Stabilité thermique améliorée. | Utile pour l'usinage à grande vitesse. |

| Carbure recyclé + Co | Respectueux de l'environnement, rentable. | Conserve d'excellentes propriétés mécaniques. |

Dureté, solidité et résistance à l'usure

| Propriété | Gamme | Influence sur la performance |

|---|---|---|

| Dureté (HV) | 850-2000 | La résistance à l'usure s'améliore avec des valeurs plus élevées. |

| Résistance à la rupture transversale | 1500-4000 MPa | Indique la capacité de charge. |

| Résistance à l'usure | Haut/Moyen/Bas | Dépend de la granulométrie et du pourcentage de liant. |

Spécifications, tailles, formes et normes

| Spécifications | Détail |

|---|---|

| Tailles | Standard : 0,5mm à 50mm ; sur mesure : Sur demande. |

| Formes | Ronde, rectangulaire, irrégulière ou spécifique à une application. |

| Normes | ISO 513, ANSI B94.25M, JIS B 4405. |

Fournisseurs et détails des prix

| Fournisseur | Région | Fourchette de prix ($/kg) | Spécialités |

|---|---|---|---|

| ABC Carbide Ltd. | Amérique du Nord | $50-$120 | Formes personnalisées, prototypage rapide. |

| Global Carbides Inc. | L'Europe | $60-$140 | Grades résistants à la corrosion. |

| Groupe Métaux d'Asie | Asie-Pacifique | $40-$100 | Prix compétitifs pour les commandes en gros. |

Comment choisir la bonne solution de carbure sur mesure ?

| Facteur | Considérations |

|---|---|

| Application | Privilégier la dureté pour l'usure, la ténacité pour la résistance aux chocs. |

| Environnement | Qualités résistantes à la corrosion pour l'exposition aux produits chimiques ou l'utilisation en milieu marin. |

| Budget | Optez pour du carbure recyclé ou des qualités standard pour les projets sensibles aux coûts. |

Comparaison des avantages et des limites

| Aspect | Avantages | Limites |

|---|---|---|

| Dureté | Résistance exceptionnelle à l'usure. | Fragile à des niveaux de dureté très élevés. |

| Personnalisation | Adapté à des besoins spécifiques. | Délais d'exécution plus longs pour la personnalisation. |

| Coût | Compétitif pour les matériaux de haute performance. | Les coûts initiaux sont plus élevés que ceux des métaux traditionnels. |

FAQ

| Question | Réponse |

|---|---|

| Quelles sont les industries qui utilisent les solutions de carbure ? | Aérospatiale, automobile, exploitation minière, médecine, pétrole et gaz, et construction. |

| Le carbure peut-il être recyclé ? | Oui, le carbure recyclé conserve d'excellentes propriétés. |

| Comment choisir le bon grade ? | Adaptez les propriétés à votre application - résistance à l'usure pour les outils, ténacité pour l'exploitation minière. |

| Les solutions en carbure sont-elles rentables ? | Si les coûts initiaux sont plus élevés, leur durabilité permet de réduire les dépenses à long terme. |

La personnalisation du carbure n'est pas qu'une question de matériaux : il s'agit de résoudre des problèmes et d'optimiser les performances. Que vous ayez besoin du foret le plus tranchant ou de la pièce la plus résistante à l'usure, solutions personnalisées en carbure peut relever vos défis les plus difficiles. Grâce aux innovations dans le domaine de la science et de l'ingénierie des matériaux, les possibilités sont pratiquement illimitées.