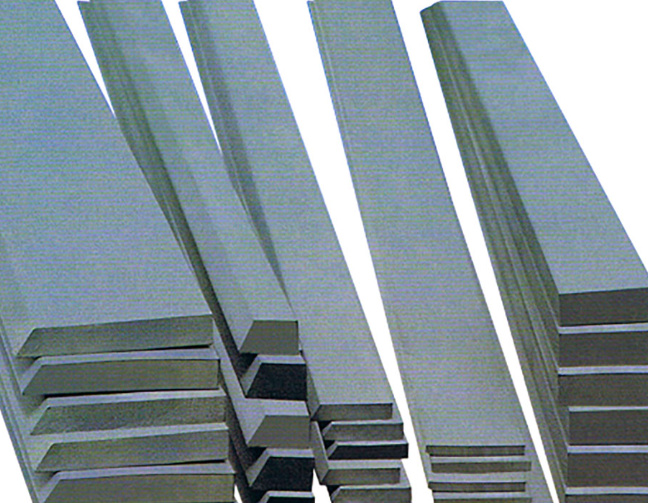

Avantages de la Tiges en carbure dans le domaine du perçage de précision

Lorsqu'il s'agit de forage de précision, les tiges en carbure sont les héros méconnus qui travaillent en coulisse. Fabriquées en carbure de tungstène, un composé de tungstène et de carbone, elles offrent une dureté et une résistance à l'usure exceptionnelles. Cela signifie qu'elles peuvent conserver leur tranchant et leur intégrité structurelle même dans des conditions de forage à grande vitesse, ce qui réduit la fréquence des remplacements d'outils et les temps d'arrêt.

L'une des principales caractéristiques des tiges de carbure est leur capacité à résister à des températures élevées sans perdre leur dureté. Cette propriété est cruciale lors des opérations de forage où la production de chaleur est inévitable. En outre, leur rigidité minimise la déviation, ce qui garantit que les trous sont percés avec une grande précision et une grande exactitude.

Applications des tiges en carbure dans le forage

Les tiges en carbure trouvent des applications dans diverses industries en raison de leurs propriétés supérieures :

- Industries aérospatiale et automobile: Utilisé dans la fabrication de composants qui requièrent une grande précision et une grande durabilité.

- Domaine médical: Essentiel pour la création d'instruments chirurgicaux et d'implants pour lesquels la précision est primordiale.

- Exploration pétrolière et gazière: Idéal pour les équipements de forage qui doivent résister à des environnements difficiles.

- Travail des métaux: Utilisé pour la fabrication de fraises, d'alésoirs et d'autres outils de coupe.

Leur polyvalence rend les tiges en carbure indispensables dans toutes les applications nécessitant un forage de précision.

Pourquoi choisir Tiges en carbure Plus d'alternatives

Lorsque l'on compare les tiges en carbure à d'autres matériaux tels que l'acier rapide (HSS) ou les alliages de cobalt, plusieurs avantages deviennent évidents :

- Dureté et résistance à l'usure: Les tiges en carbure sont nettement plus dures que les tiges en acier rapide, ce qui leur permet de couper facilement des matériaux résistants et de conserver leur tranchant plus longtemps.

- Résistance à la chaleur: Ils peuvent fonctionner à des températures plus élevées sans perdre leur dureté, contrairement aux aciers rapides qui peuvent se ramollir.

- Précision: La rigidité des tiges en carbure assure une déviation minimale, ce qui permet un perçage plus précis.

Bien que les tiges en carbure puissent avoir un coût initial plus élevé, leur longévité et leur performance se traduisent souvent par des dépenses globales moindres en raison de la réduction des changements d'outils et des temps d'arrêt.

Spécifications et guide d'achat

Lors de la sélection de tiges en carbure pour le perçage de précision, il convient de tenir compte des spécifications suivantes :

- Diamètre et longueur: Disponible en plusieurs tailles pour répondre à différentes applications.

- Grade: Les différentes qualités offrent des niveaux de dureté et de ténacité variables.

- Trous de refroidissement: Certaines tiges sont dotées de trous de refroidissement droits ou hélicoïdaux pour faciliter la dissipation de la chaleur pendant le perçage.

- Finition de la surface: Selon l'application, les tiges peuvent avoir des surfaces polies ou non polies.

Il est essentiel d'adapter les spécifications de la tige à l'application prévue pour obtenir des performances optimales.

Les 10 meilleurs modèles de poudre métallique pour Tiges en carbure

Les performances des tiges de carbure sont fortement influencées par la poudre métallique utilisée pour leur fabrication. Voici dix modèles remarquables :

| Modèle | Composition | Description |

|---|---|---|

| YG6 | 6% Cobalt | Dureté et résistance à l'usure excellentes ; idéal pour l'usinage général. |

| YG8 | 8% Cobalt | Offre un équilibre entre la dureté et la ténacité ; convient aux applications minières et de forage. |

| YG10 | 10% Cobalt | Améliore la ténacité ; utilisé pour les outils de coupe nécessitant une grande précision. |

| YG15 | 15% Cobalt | Ténacité et durabilité accrues ; parfait pour les pièces de coupe et d'usure à usage intensif. |

| YW1 | Mélange WC-Co | Nuance polyvalente présentant une bonne résistance à l'usure et une bonne ténacité. |

| YW2 | Mélange WC-Co | Similaire à YW1 mais avec une teneur en cobalt légèrement plus élevée pour une meilleure ténacité. |

| K10 | WC à grains fins | Idéal pour l'usinage de précision et les outils de coupe. |

| K20 | Mélange WC-Co | Équilibre la dureté et la ténacité ; utilisé dans le formage et la coupe des métaux. |

| C2 | Mélange WC-Co | Connu pour ses applications générales, il offre une bonne résistance à l'usure et aux chocs. |

| C3 | Mélange WC-Co | Offre une plus grande ténacité ; convient aux coupes interrompues et aux applications d'ébauche. |

La sélection du modèle de poudre métallique approprié est cruciale pour obtenir les caractéristiques de performance souhaitées dans les barres de carbure.

FAQ

| Question | Réponse |

|---|---|

| Qu'est-ce que le carbure de tungstène ? | Matériau composite composé de tungstène et de carbone, connu pour sa dureté et sa durabilité exceptionnelles. |

| Pourquoi utiliser des tiges en carbure avec des trous ? | Ils offrent une grande précision, une résistance à l'usure et une grande durabilité, ce qui les rend idéaux pour diverses applications industrielles. |

| Comment sont réalisés les trous dans les tiges de carbure ? | Généralement foré à l'aide d'un équipement spécialisé avant le processus de broyage. |

| Quelles sont les industries qui utilisent des tiges en carbure avec des trous ? | Industries manufacturières, minières, automobiles, aérospatiales, médicales et d'ingénierie. |

| Quelles sont les qualités courantes de carbure de tungstène ? | Les qualités courantes sont YG6, YG8, YG10, YG15, YW1, YW2, K10, K20, C2 et C3. |

| Comment choisir la bonne tige de carbure ? | Prenez en compte les exigences de l'application telles que la dureté, la ténacité, la résistance à l'usure, et les nuances spécifiques adaptées à ces besoins. |