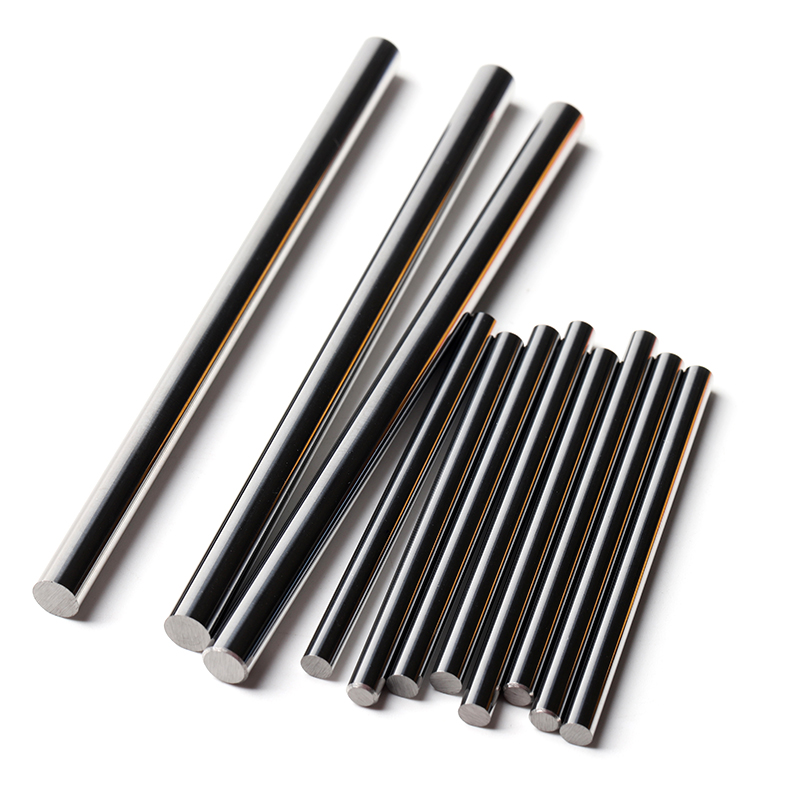

Qu'est-ce qu'une tige en carbure ?

Barres en carbure sont des barres cylindriques fabriquées principalement à partir de carbure de tungstène (WC), un composé formé par la combinaison d'atomes de tungstène et de carbone. Ces barres sont réputées pour leur dureté et leur résistance à l'usure exceptionnelles, ce qui les rend idéales pour la fabrication d'outils de coupe. Le processus de production fait appel à la métallurgie des poudres, où la poudre de carbure de tungstène est mélangée à un liant, généralement du cobalt, puis frittée pour former un barreau dense et solide. Cette méthode garantit l'uniformité de la composition et des propriétés, ce qui permet d'obtenir un matériau capable de résister aux rigueurs de l'usinage et des opérations de coupe à grande vitesse.

L'importance du matériau pour les plaquettes d'outils de coupe

Le choix du matériau pour les plaquettes d'outils de coupe est essentiel pour la performance et la longévité de l'outil. Grâce à leur dureté et à leur résistance thermique supérieures, les tiges en carbure permettent des vitesses de coupe et des avances plus élevées que les autres matériaux. Cela se traduit par une augmentation de la productivité et de l'efficacité des opérations d'usinage. De plus, la capacité du carbure à maintenir une arête de coupe tranchante réduit la fréquence des changements d'outils, minimisant ainsi les temps d'arrêt et les coûts d'exploitation.

Avantages de l'utilisation Tiges en carbure

1. Dureté et résistance à l'usure exceptionnelles : Les barres de carbure présentent un niveau de dureté supérieur à celui du diamant, ce qui leur permet de couper facilement des matériaux durs et de résister à l'usure sur de longues périodes.

2. Stabilité thermique élevée : Ils peuvent résister aux températures élevées générées pendant les processus de coupe sans perdre leur dureté, ce qui garantit des performances constantes.

3. Finition de surface améliorée : La rigidité et l'affûtage des outils en carbure permettent d'obtenir des états de surface plus lisses sur les pièces usinées, ce qui réduit la nécessité d'opérations secondaires.

4. Polyvalence : Convient à une large gamme de matériaux, y compris les aciers, les fontes, les métaux non ferreux et les superalliages.

5. Le rapport coût-efficacité : Bien que le coût initial soit plus élevé, l'allongement de la durée de vie de l'outil et la réduction des temps d'arrêt permettent de réaliser des économies globales.

Comparaison avec d'autres matériaux

| Propriété | Tiges en carbure | Acier rapide (HSS) | Céramique | Cermets |

|---|---|---|---|---|

| Dureté | Très élevé | Modéré | Haut | Haut |

| Solidité | Modéré | Haut | Faible | Modéré |

| Résistance à l'usure | Excellent | Bon | Excellent | Très bon |

| Résistance thermique | Haut | Modéré | Très élevé | Haut |

| Coût | Plus élevé | Plus bas | Haut | Modéré |

| Applications | Usinage général, matériaux durs | Matériaux souples à usage général | Finition à grande vitesse | Finition, ébauche légère |

Applications courantes des plaquettes en carbure

Les plaquettes en carbure sont utilisées dans diverses industries en raison de leur durabilité et de leur efficacité :

- Industrie automobile : Pour l'usinage de composants de moteurs, de pièces de transmission et d'autres composants critiques nécessitant précision et résistance à l'usure.

- Industrie aérospatiale : Utilisé dans la fabrication de pales de turbines, de composants structurels et d'autres pièces fabriquées à partir de matériaux difficiles à usiner.

- Travail des métaux : Idéal pour les opérations de tournage, de fraisage, de perçage et de filetage sur une variété de métaux.

- Le travail du bois : Utilisé dans les outils de coupe pour le façonnage et la finition des produits en bois.

- Fabrication de dispositifs médicaux : Pour la fabrication d'instruments chirurgicaux et d'implants nécessitant une grande précision et une biocompatibilité élevée.

Quelle est la différence entre les plaquettes en carbure et les plaquettes en acier rapide ?

Plaquettes en carbure :

- Dureté : Nettement plus dur que le HSS, il permet des vitesses de coupe plus élevées.

- Résistance à l'usure : La résistance supérieure à l'usure prolonge la durée de vie de l'outil.

- Résistance thermique : Peut supporter des températures plus élevées sans perdre sa dureté.

- Coût : Coût initial plus élevé, mais plus rentable au fil du temps en raison de la durabilité.

Plaquettes HSS :

- La robustesse : Plus ductiles, elles sont moins sujettes à l'écaillage en cas de coupes interrompues.

- Netteté des bords : Peut être affûté pour obtenir un bord plus tranchant, ce qui est utile pour certaines applications.

- Coût : Coût initial moins élevé, adapté aux opérations de faible volume ou moins exigeantes.

- Polyvalence : Plus facile à réaffûter et à modifier pour des applications personnalisées.

Modèles de poudres métalliques spécifiques pour Tiges en carbure

Le choix du modèle de poudre métallique approprié est crucial pour obtenir les caractéristiques de performance souhaitées dans les barres de carbure. Vous trouverez ci-dessous une liste de modèles spécifiques :

- YG6 : Contient du cobalt 6%, offrant une excellente dureté et résistance à l'usure. Idéal pour l'usinage général.

- YG8 : Avec le cobalt 8%, il offre un équilibre entre dureté et ténacité et convient aux applications minières et de forage.

- YG10 : Contient du cobalt 10%, ce qui améliore la ténacité. Utilisé pour les outils de coupe nécessitant une grande précision.

- YG15 : Le cobalt 15% offre une résistance et une durabilité accrues. Parfait pour les coupes lourdes et les pièces d'usure.

- YW1 : Une nuance polyvalente avec du carbure de tungstène et du cobalt, offrant une bonne résistance à l'usure et une bonne ténacité.

- YW2 : Similaire à YW1 mais avec une teneur en cobalt légèrement plus élevée pour une meilleure ténacité.

- K10 : Carbure de tungstène à grain fin, idéal pour l'usinage de précision et les outils de coupe.

- C2 : Connu pour ses applications générales, il offre une bonne résistance à l'usure et aux chocs.

- C3 : Similaire au C2 mais avec une plus grande résistance à l'usure, utilisé pour les matériaux non ferreux et non métalliques.

FAQ

| Question | Réponse |

|---|---|

| Qu'est-ce qui rend les tiges de carbure supérieures aux plaquettes d'outils de coupe ? | Leur dureté exceptionnelle, leur résistance à l'usure et leur stabilité thermique permettent d'atteindre des vitesses de coupe plus élevées et de prolonger la durée de vie de l'outil. |

| Les tiges de carbure sont-elles rentables ? | En effet, malgré un coût initial plus élevé, leur durabilité réduit la fréquence des remplacements, ce qui permet de réaliser des économies à long terme. |

| Les tiges en carbure peuvent-elles être utilisées pour tous les matériaux ? | Ils sont polyvalents et conviennent à une large gamme de matériaux, y compris les métaux durs et les composites. |

| Comment les tiges en carbure se comparent-elles aux tiges en acier rapide en termes de performance ? | Les barres en carbure offrent une dureté et une résistance à l'usure plus élevées, ce qui permet un usinage plus rapide et de meilleurs états de surface. |

| Quelles sont les limites de l'utilisation des tiges en carbure ? | Ils peuvent être plus fragiles que les aciers rapides, ce qui les rend susceptibles de s'écailler dans certaines conditions. |

| Est-il possible de réaffûter les outils en carbure ? | Oui, mais cela nécessite un équipement spécialisé en raison de leur dureté. |

| Quelles sont les industries qui bénéficient le plus des barres en carbure ? | Les industries telles que l'automobile, l'aérospatiale, le travail des métaux et la fabrication de dispositifs médicaux utilisent largement les outils en carbure. |

| Les tiges en carbure nécessitent-elles une manipulation particulière ? | Oui, en raison de leur fragilité, ils doivent être manipulés avec précaution pour éviter qu'ils ne s'écaillent ou ne se cassent. |

| Existe-t-il différentes qualités de tiges de carbure ? | Oui, différentes qualités telles que YG6, YG8 et K10 répondent à des applications spécifiques et à des exigences de performance. |

| Comment la teneur en liant affecte-t-elle les propriétés des barres de carbure ? | Une teneur plus élevée en cobalt augmente la ténacité mais peut réduire la dureté, ce qui affecte la résistance à l'usure. |