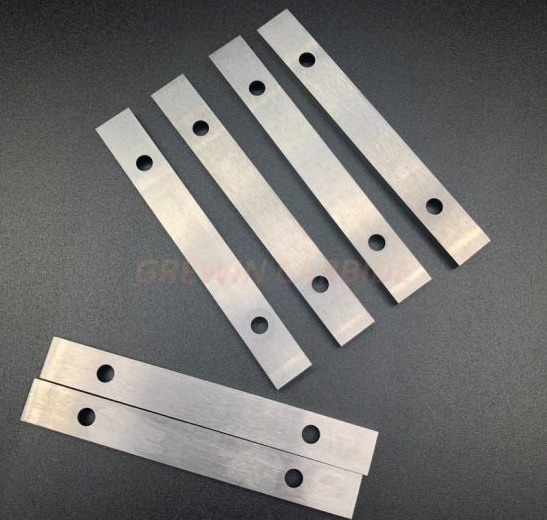

Carbure Les bandes de poinçonnage - ces outils discrets mais puissants - sont les héros méconnus d'innombrables processus de fabrication. Leur capacité à poinçonner, percer et façonner les matériaux avec une précision inébranlable les rend indispensables dans des secteurs allant de l'électronique à l'automobile. Rejoignez-nous pour plonger dans le monde fascinant des bandes de poinçonnage en carbure, en explorant leur composition, leurs applications et les facteurs qui les rendent indispensables pour les tâches de fabrication exigeantes.

Que sont exactement les bandes de poinçonnage en carbure ?

Les bandes de poinçonnage en carbure sont des pièces minces et plates en carbure cémenté, un matériau composite réputé pour sa dureté et sa résistance à l'usure exceptionnelles. Ces bandes sont spécialement conçues pour résister aux forces et aux frottements extrêmes rencontrés lors des opérations de poinçonnage et de formage. Leur secret réside dans leur composition unique :

- Carbure de tungstène : L'ingrédient principal, le carbure de tungstène, possède une dureté proche de celle du diamant, ce qui lui confère une résistance inégalée à l'usure et à l'abrasion.

- Cobalt Liant : Agissant comme une colle métallique, le cobalt lie les particules de carbure de tungstène entre elles, ce qui leur confère la ténacité et la résistance aux chocs nécessaires pour supporter des cycles de poinçonnage répétés.

De la poudre au poinçon : L'histoire de la fabrication des bandes de poinçonnage en carbure

La création de bandes de poinçonnage en carbure est un témoignage de l'ingénierie de précision :

- Métallurgie des poudres : Des poudres finement broyées de carbure de tungstène et de cobalt sont méticuleusement mélangées dans des proportions spécifiques afin d'obtenir les propriétés souhaitées pour les applications de poinçonnage.

- Pressage et mise en forme : Le mélange de poudres est ensuite soumis à une très forte pression dans des moules spécialisés, ce qui donne la forme initiale des bandes.

- Le frittage : La fusion de la force : Les bandes pressées subissent un processus de frittage à haute température dans une atmosphère contrôlée. Pendant le frittage, le liant de cobalt fond et fusionne les particules de carbure de tungstène, formant un matériau solide et incroyablement dense.

- Rectification et finition de précision : Après le frittage, les bandes de carbure sont méticuleusement rectifiées et finies pour obtenir les dimensions précises, les tolérances et la qualité de surface requises pour les applications de poinçonnage.

Une bande pour chaque poinçon : Types et propriétés des bandes de carbure pour poinçons

Les bandes de poinçonnage en carbure ne constituent pas une solution unique. Elles existent en différentes qualités, tailles et configurations, chacune adaptée à des applications de poinçonnage et à des matériaux spécifiques. Voici un aperçu de leur diversité :

Bandes de poinçonnage en carbure : Décoder leurs propriétés

| Propriété | Description | Valeurs typiques |

|---|---|---|

| Dureté (HRA) | Résistance à la rayure et à l'indentation | 88-95 |

| Résistance à la rupture transversale (TRS) | Capacité à résister aux forces de flexion sans se rompre | 1500-3000 N/mm² |

| Résistance à la compression | Résistance à la déformation sous compression | 4000-6000 N/mm² |

| Taille des grains | Taille des particules de carbure de tungstène, influençant la dureté et la résistance à l'usure | 0,5-10 µm |

| Teneur en cobalt | Pourcentage de liant cobalt, ayant un impact sur la ténacité et la résistance à l'usure | 6-12% |

Tableau 1 : Propriétés principales des bandes de poinçonnage en carbure

Des poinçons plus forts que leur poids : Applications des bandes de poinçonnage en carbure

Les bandes de poinçonnage en carbure sont la force motrice du poinçonnage de précision dans une multitude d'industries :

1. L'électronique : Façonner le monde numérique

- Cartes de circuits imprimés (PCB) : Les bandes de poinçonnage en carbure créent des trous et des découpes précises dans les circuits imprimés pour le montage de composants électroniques, garantissant ainsi des connexions de circuit précises.

- Fabrication de semi-conducteurs : Utilisé dans les processus de découpage et d'emballage des plaquettes, il assure une séparation et une manipulation précises des puces semi-conductrices délicates.

2. Automobile : La précision dans chaque pièce

- Emboutissage du métal : Les bandes de poinçonnage en carbure créent des trous, des fentes et d'autres caractéristiques dans les pièces en tôle pour les carrosseries, les cadres et les composants automobiles.

- Systèmes d'injection de carburant : Utilisé pour fabriquer des buses et des composants précis pour les systèmes d'injection de carburant, garantissant une atomisation optimale du carburant et des performances du moteur.

3. Au-delà de la chaîne d'assemblage :

La polyvalence des bandes de poinçonnage en carbure s'étend à un large éventail d'autres industries, notamment :

- Aérospatiale : Perçage de trous et de fentes dans des matériaux légers pour des composants aéronautiques.

- Médical : Création d'ouvertures et de caractéristiques précises dans les instruments chirurgicaux et les dispositifs médicaux.

- Emballage : Fabrication de matrices pour la découpe et la mise en forme de matériaux d'emballage.

L'avantage concurrentiel : comparaison des fournisseurs de bandes de poinçonnage en carbure

| Fournisseur | Localisation | Fourchette de prix (par pièce) | Spécialités |

|---|---|---|---|

| TRUER | Mondial | $10 – $80 | Sur mesure solutions en carburegrades de haute performance pour les applications de poinçonnage exigeantes |

| Élément six | Mondial | $15 – $100 | Large gamme de nuances standard et spécialisées, revêtements avancés pour une durée de vie prolongée des outils |

| Sandvik Coromant | Suède | $20 – $120 | Géométries et revêtements avancés pour le poinçonnage à haut volume et les matériaux difficiles |

| Kennametal | ÉTATS-UNIS | $12 – $90 | Bandes de poinçonnage en carbure de haute qualité pour diverses industries, y compris l'automobile et l'électronique |

Tableau 2 : Comparaison des fournisseurs de bandes de poinçonnage en carbure

Remarque : Les prix sont approximatifs et peuvent varier en fonction de la qualité, de la taille, de la quantité et des conditions du marché.

Une perspective équilibrée : Avantages et limites des bandes de poinçonnage en carbure

Bandes de poinçonnage en carbure : Peser le pour et le contre

| Avantages | Limites |

|---|---|

| Dureté et résistance à l'usure exceptionnelles, garantissant une longue durée de vie de l'outil | Relativement fragile, susceptible de s'écailler ou de se fracturer en cas d'impact extrême ou de charges latérales |

| Haute précision dimensionnelle et précision, permettant la création de pièces complexes | Peut être coûteux par rapport à d'autres matériaux d'outillage, en particulier pour les géométries complexes. |

| Capacité à poinçonner une large gamme de matériaux, des feuilles minces aux plaques épaisses | Nécessite un équipement et une expertise spécialisés pour l'usinage et l'affûtage. |

| Résistance aux températures et aux pressions élevées, ce qui les rend aptes à des applications exigeantes | Peut ne pas convenir à toutes les applications de poinçonnage, en particulier celles qui impliquent des trous de très grande taille ou de forme irrégulière. |

Tableau 3 : Avantages et limites des bandes de poinçonnage en carbure

Au-delà de la presse à poinçonner : Faits intéressants sur le carbure

- De l'exploitation minière à la fabrication : Le tungstène, principal composant du carbure de tungstène, tire son nom des mots suédois "tung sten", qui signifient "pierre lourde". Il a d'abord été utilisé dans les outils miniers en raison de son extrême dureté.

- Un matériau des extrêmes : Le carbure de tungstène a le point de fusion le plus élevé de tous les métaux, atteignant 3 422 degrés Celsius (6 192 degrés Fahrenheit).

- Un choix durable : Le carbure de tungstène est un matériau incroyablement durable, et les outils fabriqués à partir de ce matériau peuvent être réaffûtés plusieurs fois, ce qui permet de réduire les déchets et de promouvoir le développement durable.

Pourquoi choisir TRUER pour vos besoins en bandes de poinçonnage en carbure ?

Chez TRUER, nous nous engageons à fournir des solutions en carbure qui permettent à nos clients d'atteindre des performances de poinçonnage exceptionnelles. Voici pourquoi TRUER se distingue :

- Une qualité sans compromis : Nous nous procurons des matériaux en carbure de tungstène de la plus haute qualité et appliquons des mesures strictes de contrôle de la qualité tout au long de notre processus de fabrication.

- Solutions personnalisées : Nous sommes spécialisés dans la fabrication de bandes de poinçonnage en carbure pour répondre à vos spécifications uniques, qu'il s'agisse de la nuance, de la géométrie, de la taille ou de la finition.

- Expertise technique : Notre équipe d'experts en carbure fournit des conseils et une assistance, vous aidant à sélectionner la solution carbure optimale pour votre application de poinçonnage.

- Une portée mondiale : Grâce à notre présence mondiale, nous assurons une livraison dans les délais et un service clientèle réactif, où que vous soyez dans le monde.

FAQs : Réponses à vos questions sur les bandes de poinçonnage en carbure

1. Quels sont les facteurs qui influencent la durée de vie d'une bande de poinçon en carbure ?

La durée de vie d'une bande de poinçon en carbure dépend de plusieurs facteurs :

– Qualité du carbure : Les bandes de carbure de qualité supérieure offrent généralement une durée de vie plus longue.

– Matière à perforer : Le poinçonnage de matériaux abrasifs ou très résistants peut réduire la durée de vie de l'outil.

– Conditions de poinçonnage : La vitesse de poinçonnage, la lubrification et l'épaisseur du matériau influencent les taux d'usure.

– Entretien : Un affûtage, un nettoyage et un stockage adéquats peuvent considérablement prolonger la durée de vie des bandes de poinçons en carbure.

2. Les bandes de poinçonnage en carbure peuvent-elles être revêtues ?

Oui, les bandes de poinçonnage en carbure peuvent être revêtues de divers matériaux afin d'améliorer leurs performances. Les revêtements les plus courants sont les suivants

– Nitrure de titane (TiN) : Augmente la dureté, réduit le frottement et améliore la résistance à l'usure.

– Carbonitrure de titane (TiCN) : Offre une dureté et une résistance à l'usure encore plus élevées que le TiN.

– Carbone semblable à un diamant (DLC) : Offre un pouvoir lubrifiant et une résistance à l'usure exceptionnels, en particulier pour le poinçonnage de matériaux abrasifs.

3. Quelles sont les principales considérations à prendre en compte lors de la conception d'un jeu de poinçons et de matrices utilisant des bandes de carbure ?

La conception de jeux de poinçons et de matrices efficaces utilisant des bandes de carbure implique la prise en compte de facteurs tels que

– Effacement : L'espace entre le poinçon et la matrice, crucial pour contrôler le flux de matière et éviter les dommages.

– Force de déshabillage : La force nécessaire pour retirer le matériau poinçonné de la matrice, ce qui influence la conception du poinçon et de la matrice.

– Épaisseur et propriétés du matériau : Le type et l'épaisseur du matériau poinçonné ont un impact sur la géométrie du poinçon et de la matrice.

4. Comment choisir la bonne nuance de carbure pour mon application de poinçonnage ?

La sélection de la nuance de carbure appropriée implique la prise en compte de facteurs tels que

– Matière à perforer : Différentes qualités de carbure sont optimisées pour le poinçonnage de matériaux spécifiques (acier, aluminium, cuivre, etc.).

– Force et vitesse de frappe : Des forces et des vitesses plus élevées peuvent nécessiter des carbures plus résistants.

– Durée de vie requise de l'outil : Les applications exigeant une longue durée de vie de l'outil bénéficient de bandes de carbure de qualité supérieure.

5. Quelles sont les précautions à prendre pour manipuler et utiliser les bandes de poinçonnage en carbure ?

En raison de leur extrême dureté et de leur potentiel d'écaillage, les bandes de poinçonnage en carbure doivent être manipulées avec précaution :

– Porter des lunettes de sécurité : Protégez vos yeux des éclats et des débris.

– Utiliser des gants : Prévenir les coupures dues aux arêtes tranchantes.

– A manipuler avec précaution : Évitez de faire tomber ou de heurter les bandes pour éviter qu'elles ne s'écaillent ou ne se cassent.