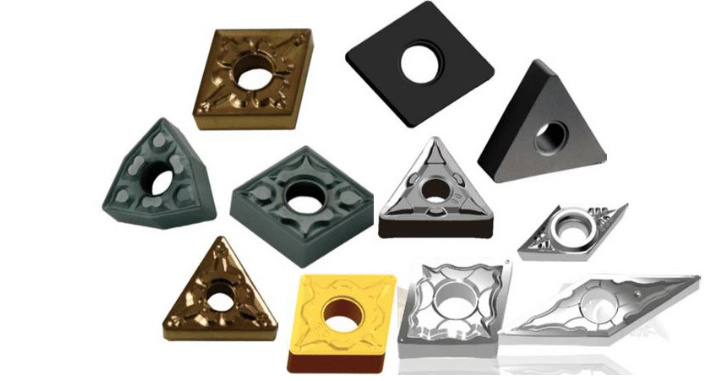

Qu'est-ce qu'un Plaque de carbure?

Les plaques de carbure sont des composants métalliques à haute performance fabriqués principalement à partir de carbure de tungstène (WC), souvent liés à du cobalt (Co) ou à d'autres liants pour améliorer les propriétés mécaniques. Ces plaques sont largement utilisées dans les applications industrielles nécessitant une résistance extrême à l'usure et à la corrosion.

Facteurs affectant la résistance à la corrosion

Les plaques de carbure sont robustes, mais leur résistance à la corrosion dépend de plusieurs facteurs. Décortiquons-les :

1. Composition du liant

Le choix du liant joue un rôle crucial dans la résistance à la corrosion. Par exemple :

- Cobalt (Co): Améliore la ténacité mais est plus sensible à la corrosion dans les environnements acides.

- Nickel (Ni): Offre une meilleure résistance à la corrosion que le cobalt, en particulier dans les applications marines et chimiques.

- Additions de chrome (Cr): Améliore la résistance à l'oxydation et aux attaques acides.

2. Taille des grains de la poudre de carbure

Des grains de carbure plus fins entraînent une densité plus élevée et une porosité moindre, ce qui rend le matériau moins sujet à la corrosion. Les gros grains peuvent introduire des points faibles où les agents corrosifs peuvent pénétrer.

3. Facteurs environnementaux

L'exposition à des conditions extrêmes telles qu'une forte humidité, des solutions acides ou de l'eau salée peut accélérer la corrosion. La compréhension de l'environnement de travail permet de sélectionner la bonne composition de carbure.

4. Traitements de surface et revêtements

L'application d'un revêtement protecteur, tel que le TiN (nitrure de titane) ou l'Al2O3 (oxyde d'aluminium), peut améliorer considérablement la résistance à la corrosion.

Avantages de la Plaques de carbure dans les environnements corrosifs

Pourquoi les industries devraient-elles choisir les plaques en carbure plutôt que les métaux conventionnels ? Voici quelques avantages convaincants :

- Dureté et résistance supérieures: Contrairement à l'acier inoxydable, les plaques en carbure conservent leur intégrité même en cas de contraintes et de fluctuations de température extrêmes.

- Durée de vie prolongée: Une résistance élevée à l'usure et à la corrosion permet de réduire les coûts de remplacement et les temps d'arrêt.

- Stabilité chimique: Idéal pour les applications chimiques difficiles où d'autres métaux peuvent se dégrader rapidement.

- Tolérance aux températures élevées: Le carbure reste structurellement sain à des températures où l'acier et l'aluminium peuvent s'affaiblir.

Applications des plaques de carbure résistant à la corrosion

| L'industrie | Application | Exposition à la corrosion |

|---|---|---|

| Pétrole et gaz | Outils de forage, vannes, joints de pompe | Eau de mer, pétrole brut |

| Traitement chimique | Échangeurs de chaleur, revêtements de réacteurs | Produits chimiques acides et alcalins |

| Aérospatiale | Composants de moteurs, buses haute pression | Températures extrêmes, humidité |

| Marine | Arbres d'hélices, composants de navires | Corrosion par l'eau salée |

| Exploitation minière | Plaques transporteuses résistantes à l'usure | Humidité, abrasifs |

Comment améliorer la résistance à la corrosion des Plaques de carbure?

| Méthode | Description | Efficacité |

|---|---|---|

| Optimisation du liant | L'utilisation de liants à base de Ni ou de Cr au lieu de Co | Haut |

| Structure des nanograins | Les grains de carbure plus fins réduisent la porosité | Haut |

| Revêtements de surface | Revêtements TiN, Al2O3 ou PVD pour la protection | Très élevé |

| Traitements chimiques | Techniques de passivation pour améliorer la stabilité de la surface | Modéré |

| Compléments d'alliage | Incorporation d'éléments tels que le vanadium ou le chrome | Haut |

Caractéristiques de résistance à la corrosion et valeur d'application des plaques de carbure

Les plaques de carbure sont d'une valeur inestimable dans les industries qui exigent une durabilité extrême. Avec la bonne composition du matériau et les mesures de protection adéquates, leur résistance à la corrosion peut égaler, voire dépasser, celle de l'acier inoxydable traditionnel. Comparées à d'autres solutions telles que les aciers fortement alliés, les plaques en carbure offrent une longévité, une rentabilité et des performances supérieures dans les environnements agressifs.

Les 10 meilleurs modèles de poudres de carbure résistantes à la corrosion

| Modèle de poudre de carbure | Composition | Meilleur pour les applications |

|---|---|---|

| WC-Co (6%) | Carbure de tungstène, 6% Cobalt | Outils de coupe, pièces d'usure |

| WC-Ni (8%) | Carbure de tungstène, 8% Nickel | Traitement chimique, marine |

| WC-CrC-Ni | Carbure de tungstène, carbure de chrome, nickel | Aérospatiale, environnements à haute température |

| TiC-WC-Co | Carbure de titane, carbure de tungstène, cobalt | Usinage à grande vitesse |

| WC-Co-Cr | Carbure de tungstène, Cobalt, Chrome | Revêtements résistants à la corrosion |

| WC-NiMoCr | Carbure de tungstène, nickel, molybdène, chrome | Industrie pétrolière et gazière |

| WC-Co-V | Carbure de tungstène, Cobalt, Vanadium | Environnements abrasifs |

| WC-FeNi | Carbure de tungstène, fer, nickel | Applications industrielles lourdes |

| WC-Cr3C2 | Carbure de tungstène, carbure de chrome | Résistance extrême à l'usure |

| WC-Al2O3 | Carbure de tungstène, oxyde d'aluminium | Résistance thermique élevée |

FAQ

| Question | Réponse |

|---|---|

| Les plaques de carbure sont-elles totalement insensibles à la corrosion ? | Non, mais ils ont une résistance élevée en fonction du liant et du revêtement utilisés. |

| Comment choisir la meilleure plaque de carbure pour mon application ? | Tenez compte de facteurs tels que l'environnement, la température et l'exposition aux produits chimiques. Les liants à base de nickel sont les plus efficaces pour la résistance à la corrosion. |

| Les plaques en carbure peuvent-elles être utilisées dans des applications en eau de mer ? | Oui, en particulier ceux qui contiennent des liants à base de nickel et des revêtements protecteurs comme le CrC. |

| Quels sont les revêtements qui peuvent améliorer la résistance à la corrosion du carbure ? | Les revêtements TiN, Al2O3 et PVD offrent une excellente protection. |

| Comment les plaques en carbure se comparent-elles à l'acier inoxydable ? | Le carbure est plus dur et plus résistant à l'usure, mais l'acier inoxydable peut être préférable dans certains cas en raison de son coût moins élevé et de sa plus grande flexibilité. |