L'efficacité au charbon : 2 modèles de boutons en carbure pour des performances supérieures

La demande incessante de charbon en tant que source d'énergie vitale nécessite des opérations minières robustes et efficaces. Au cœur de cette industrie exigeante se trouvent l'exploitation du charbon carbure boutonsLes boutons sont conçus pour résister aux conditions difficiles de l'extraction souterraine et à ciel ouvert du charbon. Ce guide se concentre sur deux modèles de boutons clésconique et en forme de champignon-en dévoilant leurs avantages uniques et la manière dont ils contribuent à maximiser la productivité et à minimiser les temps d'arrêt dans les applications d'extraction du charbon.

Pourquoi les boutons en carbure sont indispensables dans les mines de charbon

Au-delà des pièces d'usure ordinaires : Comprendre la proposition de valeur

- Dureté inégalée : Le carbure de tungstène, le matériau de base de ces boutons, possède une dureté exceptionnelle, supérieure à la plupart des métaux et à la dureté du charbon et des formations rocheuses environnantes.

- Résistance supérieure à l'usure : Cette dureté inhérente se traduit par une résistance à l'usure exceptionnelle, permettant aux boutons en carbure de résister aux forces abrasives rencontrées lors de l'extraction du charbon, prolongeant la durée de vie de l'outil et réduisant les coûts de maintenance.

- Résistance à l'impact : Les opérations d'extraction du charbon impliquent des impacts et des chocs importants. Les boutons en carbure sont conçus pour absorber ces forces, ce qui évite les défaillances prématurées et garantit des performances constantes.

Forme conique ou forme de champignon : Décoder les différences de conception

La forme dicte la fonction : Comment la géométrie influence les performances

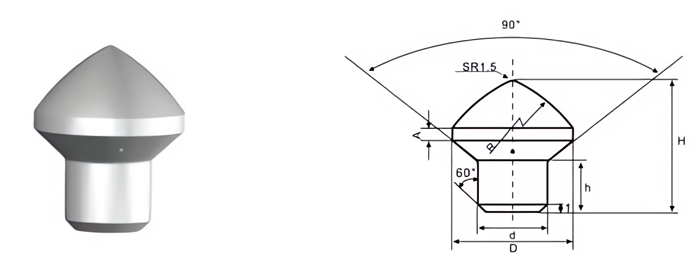

1. Boutons coniques :

- Caractéristiques : Ces boutons ont une forme conique et effilée avec un bout pointu, conçu pour une pénétration agressive.

- Avantages : Excellente pour couper et briser les veines de charbon dur et les strates rocheuses, offrant des taux de forage élevés et un enlèvement efficace des matériaux.

- Idéal pour : Applications de forage rotatif, pics de coupe pour les mineurs continus et autres outils nécessitant une action de coupe ciblée.

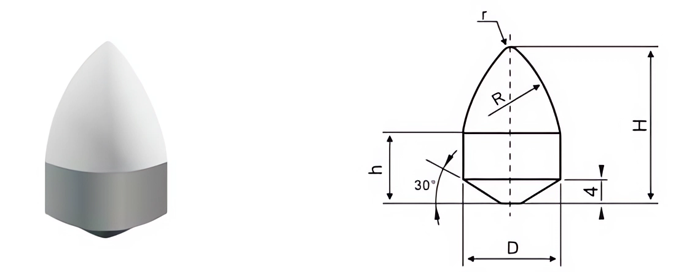

2. Boutons en forme de champignon :

- Caractéristiques : Ces boutons ont une forme caractéristique de dôme ou de champignon avec une surface supérieure plus large et aplatie.

- Avantages : Ils offrent un équilibre entre la pénétration et la résistance à l'usure, ce qui les rend adaptés aux applications impliquant à la fois des actions de coupe et d'écrasement. La surface plus large permet également de mieux répartir l'usure.

- Idéal pour : Toupies, cisailles et autres équipements d'extraction du charbon où une combinaison de coupe, de grattage et de concassage est nécessaire.

Spécifications techniques : Un regard comparatif sur les propriétés des boutons

De la composition aux normes : Points clés

| Fonctionnalité | Boutons coniques | Boutons en forme de champignon |

|---|---|---|

| Type | Conique | En forme de champignon |

| Composition | Carbure de tungstène (WC) avec liant de cobalt (Co) ou de nickel (Ni) | Carbure de tungstène (WC) avec liant de cobalt (Co) ou de nickel (Ni) |

| Dureté (HV30) | 1500 – 1900 | 1450 – 1850 |

| Résistance à la rupture transversale (N/mm²) | 1900 – 2600 | 1850 – 2550 |

| Résistance aux chocs | Très bon | Bon |

| Résistance à l'usure | Très bon pour les applications de pénétration et de coupe | Bon équilibre entre la résistance à l'usure et à la pénétration |

| Tailles et formes | Différents diamètres et angles de pointe disponibles | Différents diamètres et hauteurs de dôme disponibles |

| Niveaux et normes | Respecter les normes ISO, ASTM et autres normes industrielles pertinentes | Respecter les normes ISO, ASTM et autres normes industrielles pertinentes |

Applications dans les mines de charbon : Les points forts de chaque type de bouton

De l'extraction à la manutention : Une série de cas d'utilisation

- Exploitation souterraine du charbon :

- Mineurs en continu : Les boutons coniques sont couramment utilisés sur les tambours rotatifs des mineurs continus pour leur capacité de coupe agressive dans les veines de charbon.

- Road Headers : Les boutons en forme de champignon sont souvent préférés sur les collecteurs routiers, qui coupent et chargent le charbon simultanément, en raison de leur équilibre entre la résistance à l'usure et la résistance à la pénétration.

- L'exploitation minière par longues parois : Les boutons coniques et les boutons en forme de champignon sont tous deux utilisés dans les cisailles à longue taille, le choix dépendant des conditions géologiques spécifiques et des exigences de coupe.

- Exploitation du charbon à ciel ouvert :

- Forage et dynamitage : Les boutons coniques sont utilisés dans les trépans pour le forage de trous de mine dans les mines à ciel ouvert en raison de leur capacité de pénétration efficace.

- Godets pour dragline : Des boutons en forme de champignon sont souvent incorporés dans les dents et les arêtes de coupe des godets de dragline pour leur capacité à résister aux forces abrasives de l'écopage et du chargement du charbon.

Analyse comparative : TRUER vs. les leaders de l'industrie

Naviguer sur le marché : Une comparaison côte à côte

| Fournisseur | Localisation | Pays | Fourchette de prix (par pièce) | Spécialités |

|---|---|---|---|---|

| TRUER | Shanghai, Chine | Chine | $10 – $50+ | Solutions sur mesure, prototypage rapide, soutien exceptionnel à la clientèle |

| Élément six | Siège mondial : Londres, Royaume-Uni | ROYAUME-UNI | $16 – $65+ | Science des matériaux avancée, nuances de carbure haute performance pour les applications d'usure extrême |

| Kennametal | Siège mondial : Pittsburgh, PA | ÉTATS-UNIS | $13 – $55+ | Large gamme de boutons standard et personnalisés, vaste expérience dans l'industrie |

| Sandvik Coromant | Siège mondial : Sandviken, Suède | Suède | $15 – $70+ | Solutions d'outillage innovantes, axées sur la durabilité et l'optimisation des performances |

Remarque : Les prix sont approximatifs et peuvent varier considérablement en fonction de la taille, de la géométrie, de la qualité, de la quantité et d'autres facteurs.Si vous souhaitez acheter des boutons en carbure abordables, résistants à la corrosion et durables, cliquez sur ici.

Avantages et limites : Peser le pour et le contre

Prendre des décisions éclairées : Une vision équilibrée de chaque type de bouton

| Type de bouton | Avantages | Limites |

|---|---|---|

| Conique | - Taux de pénétration élevé, idéal pour le charbon et les roches dures<br> - Enlèvement efficace de la matière, permettant un perçage et une coupe plus rapides | - Peut être sujet à des ruptures sous des charges latérales extrêmes<br> - Taux d'usure plus élevés que les boutons en forme de champignon dans les applications impliquant un raclage et un écrasement importants. |

| En forme de champignon | - Bon équilibre entre la pénétration et la résistance à l'usure<br> - La surface plus large répartit l'usure plus uniformément<br> - Convient pour une combinaison d'actions de coupe, de grattage et de broyage | - Taux de pénétration inférieur à celui des boutons coniques<br> - Pas idéal pour les applications nécessitant une coupe agressive dans des formations très dures |

Au-delà de l'essentiel : Facteurs influençant la performance et la longévité des boutons

Maximiser le retour sur investissement : Considérations clés

- Sélection de la qualité du carbure : Le choix de la qualité appropriée de carbure de tungstène est crucial, compte tenu de facteurs tels que la dureté du charbon et de la roche, les exigences en matière de résistance aux chocs et la présence de minéraux abrasifs.

- Bouton Méthode de fixation : Des techniques de brasage ou de soudage appropriées sont essentielles pour assurer une liaison solide entre le bouton et l'outil d'extraction, afin d'éviter la perte prématurée du bouton.

- Paramètres de fonctionnement : Des facteurs tels que la vitesse de coupe, la profondeur de coupe et l'utilisation de fluides de coupe peuvent influencer de manière significative les taux d'usure des boutons et les performances globales.

Pourquoi choisir TRUER ?

Votre partenaire en matière d'efficacité des mines de charbon :

TRUER s'engage à fournir plus que de simples boutons en carbure ; nous offrons des solutions sur mesure pour optimiser vos opérations d'extraction du charbon. Voici pourquoi les leaders de l'industrie choisissent TRUER :

- Qualité inébranlable : Nous ne nous approvisionnons qu'en carbure de tungstène de la plus haute qualité et adhérons à des mesures rigoureuses de contrôle de la qualité tout au long de notre processus de fabrication.

- Expertise en matière de personnalisation : Notre équipe d'ingénieurs excelle dans la conception et la fabrication de boutons sur mesure pour répondre à vos défis spécifiques en matière d'exploitation minière.

- Prototypage et production rapides : Nous comprenons l'importance de minimiser les temps d'arrêt dans l'industrie minière. Nos processus rationalisés nous permettent de livrer efficacement des prototypes et des séries de production.

- Un soutien exceptionnel à la clientèle : Nous sommes à vos côtés à chaque étape du processus, en vous fournissant des conseils techniques et une assistance d'experts pour garantir votre succès.

Foire aux questions : Répondre à vos questions sur les boutons d'extraction du charbon

1. Comment choisir le type et la qualité de bouton en carbure qui conviennent à mon application spécifique d'extraction de charbon ?

Le type et la qualité optimaux du bouton dépendent de facteurs tels que la dureté de la veine de charbon, le type d'équipement minier utilisé et l'équilibre souhaité entre la pénétration et la résistance à l'usure. Il est recommandé de consulter nos experts techniques pour obtenir des conseils personnalisés.

2. Quelles sont les formes d'usure typiques observées sur les boutons coniques et les boutons en forme de champignon, et comment puis-je identifier le moment où un remplacement est nécessaire ?

Les schémas d'usure varient en fonction du type de bouton et des conditions d'utilisation. Les signes d'usure les plus courants sont l'émoussement ou l'écaillage de la pointe des boutons coniques et l'aplatissement ou le rainurage de la surface supérieure des boutons en forme de champignon. Il est essentiel de procéder à des inspections régulières et à des remplacements en fonction des limites d'usure établies.

3. TRUER peut-il fournir des boutons en carbure avec des revêtements spécialisés pour une meilleure résistance à l'usure ou à la corrosion dans les environnements exigeants des mines de charbon ?

Oui, nous proposons une gamme de traitements de surface et de revêtements qui peuvent améliorer les performances et la longévité de nos boutons en présence de minéraux abrasifs, d'agents corrosifs et d'autres conditions difficiles.

4. Quel est le délai de livraison habituel pour commander des boutons en carbure personnalisés auprès de TRUER ?

Les délais d'exécution des commandes personnalisées varient en fonction de la complexité du dessin et de la quantité requise. Contactez notre équipe commerciale pour obtenir un devis personnalisé et une estimation des délais.

5. TRUER propose-t-il une assistance technique ou une formation sur site concernant l'utilisation et l'entretien de ses boutons en carbure dans les mines de charbon ?

Nous fournissons une assistance technique complète, y compris des consultations sur site, des programmes de formation et une assistance au dépannage, pour vous permettre de tirer le meilleur parti de nos produits et d'optimiser vos opérations d'extraction du charbon.