Qu'est-ce que le carbure et pourquoi excelle-t-il sous haute pression ?

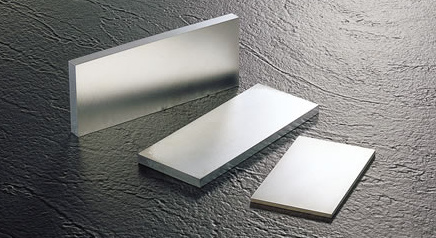

Carbure change la donne en matière d'environnements extrêmes. Mais qu'est-ce qui le rend si spécial ? Imaginez un matériau si résistant qu'il peut supporter des pressions insensées sans transpirer. C'est le carbure ! Le carbure est un matériau composite composé de carbures métalliques (comme le carbure de tungstène, le carbure de titane ou le carbure de tantale) liés à un liant métallique tel que le cobalt ou le nickel.

Le carbure se distingue par son extrême dureté et sa capacité à conserver son intégrité structurelle dans des conditions de pression et de température élevées, ainsi que dans des conditions corrosives. Contrairement à l'acier, qui se déforme sous la pression, le carbure résiste, ce qui en fait le choix idéal pour les industries qui repoussent les limites des matériaux.

Propriétés clés de Carbure pour des conditions extrêmes

Dans les applications à haute pression, le carbure possède un ensemble de propriétés qui le rendent indispensable :

- Dureté exceptionnelle : Le carbure est presque aussi dur que le diamant, ce qui garantit sa durabilité dans des conditions extrêmes.

- Résistance élevée à la compression : Contrairement à d'autres métaux, le carbure peut résister à des forces massives sans se déformer.

- Résistance supérieure à l'usure : Idéal pour la coupe, le perçage et les environnements à fort coefficient de frottement.

- Stabilité thermique : Résiste à des températures supérieures à 1000°C sans perdre ses propriétés.

- Résistance à la corrosion : Essentiel pour les environnements chimiques difficiles, en particulier dans les forages pétroliers et gaziers.

Applications du carbure dans les environnements à haute pression

La robustesse du carbure en fait un matériau de choix pour les industries soumises à des pressions extrêmes. Jetons un coup d'œil à quelques applications clés :

Forage de pétrole et de gaz

- Utilisé dans forets, buses et pièces d'usure où les conditions souterraines de haute pression exigent une résistance à toute épreuve.

Ingénierie aérospatiale

- Essentiel pour les composants de turbine, les outils de coupe et les revêtements de protection dans les moteurs à réaction à haute pression.

Exploitation minière et forage de la terre

- Trépans, inserts de forage et arêtes de coupe pour l'écrasement des roches utilisent le carbure pour résister aux forces intenses de l'excavation souterraine.

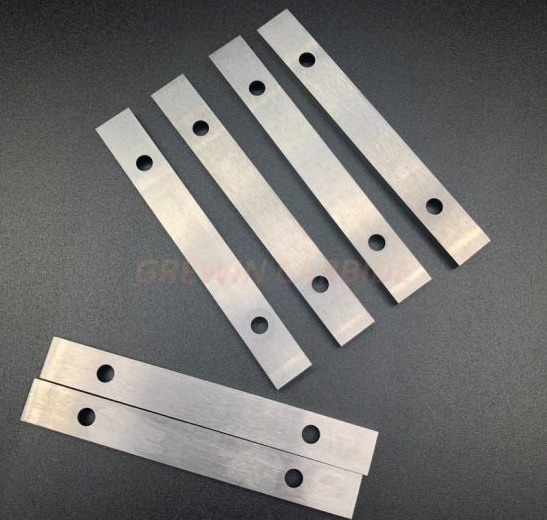

Fabrication et travail des métaux

- Outils de coupe, matrices de formage et matrices d'extrusion la résistance du carbure à la déformation sous l'effet d'une forte contrainte mécanique.

Industrie automobile

- Les moteurs à hautes performances s'appuient sur sièges de soupapes, injecteurs et outils d'usinage de précision pour supporter des pressions et des variations de température extrêmes.

Comment choisir le bon Carbure pour votre demande

| Type de carbure | Dureté (HV) | Résistance à la compression (MPa) | Meilleur pour |

|---|---|---|---|

| Carbure de tungstène (WC-Co) | 1400-2000 | 4000-6000 | Forage, exploitation minière, usinage |

| Carbure de titane (TiC) | 1800-2800 | 4500-6000 | Outils de coupe, applications aérospatiales |

| Carbure de tantale (TaC) | 2000-3000 | 5000-6500 | Environnements à haute température |

| Carbure de chrome (CrC) | 1200-2000 | 3000-5000 | Revêtements résistants à l'usure |

| Carbure de niobium (NbC) | 1800-2800 | 4500-6000 | Revêtements à barrière thermique, outils de coupe |

Tendances futures dans le développement du carbure haute pression

| Tendance | Description |

|---|---|

| Carbures nanostructurés | Résistance accrue et résistance à l'usure au niveau micro. |

| Carbures hybrides | Combinaison de plusieurs types de carbures pour une performance optimale. |

| Carbures imprimés en 3D | Formes personnalisables pour les applications spécialisées à haute pression. |

| Technologies de revêtement | Revêtements avancés pour améliorer la résistance à la corrosion et à l'usure. |

| Reliures écologiques | Réduire l'utilisation du cobalt et du nickel pour une production durable. |

FAQ

| Question | Réponse |

|---|---|

| Quel est le type de carbure le plus résistant ? | Le carbure de tungstène (WC) est largement considéré comme le plus solide, offrant la meilleure combinaison de dureté et de ténacité. |

| Le carbure peut-il se briser sous l'effet de la pression ? | Si le carbure est incroyablement résistant, il est également fragile. S'il est soumis à un impact soudain, il peut se fissurer. Toutefois, dans des environnements contrôlés à haute pression, il est plus performant que la plupart des métaux. |

| Comment le carbure se compare-t-il à l'acier ? | Le carbure est nettement plus dur et plus résistant à l'usure que l'acier, mais il est aussi plus fragile. Il est donc idéal pour des applications spécifiques telles que les outils de coupe et le forage. |

| Le carbure est-il cher ? | Il est vrai que le carbure est généralement plus cher que l'acier en raison de ses propriétés supérieures. Toutefois, sa durabilité compense souvent le coût dans les applications à long terme. |

| Quelles sont les industries qui utilisent le plus le carbure ? | Les industries aérospatiale, pétrolière et gazière, minière, manufacturière et automobile dépendent du carbure pour sa résistance et sa durabilité inégalées. |