Construire un avenir plus fort : Explication des boutons de brise-route, de forage rotatif, de roulage et de tunnelier

Des gratte-ciel aux tunnels souterrains complexes, les projets de construction exigent des outils et des matériaux capables de résister à une pression immense et à une usure incessante. Carbure de tungstène boutons se sont imposés comme des composants indispensables dans cette industrie exigeante, offrant une dureté et une durabilité inégalées. Ce guide se penche sur quatre types clés de boutons en carbure - brise-route, forage rotatif, laminage et pointes pour tunneliers - révélant leurs caractéristiques uniques et la façon dont ils contribuent à construire un avenir plus fort et plus résilient.

Pourquoi les boutons en carbure de tungstène constituent-ils l'épine dorsale de la construction ?

Au-delà des pièces d'usure ordinaires : Comprendre la proposition de valeur

- Dureté exceptionnelle : Le carbure de tungstène, un matériau composite réputé pour son extrême dureté, constitue le cœur de ces boutons en carbure de tungstène, ce qui leur permet de résister à l'usure, même dans les conditions de construction les plus exigeantes.

- Résistance aux chocs et à l'abrasion : Les chantiers de construction sont soumis à des impacts, des chocs et des forces abrasives. Les boutons en carbure de tungstène sont conçus pour résister à ces défis, assurer leur longévité et minimiser les temps d'arrêt.

- Polyvalence dans l'application : Qu'il s'agisse de percer la roche ou de percer des trous précis, chaque type de bouton en carbure de tungstène est spécialement conçu pour exceller dans son application respective, optimisant ainsi l'efficacité et la performance.

Décoder les modèles : Boutons de brise-route, de forage rotatif, de roulage et de tunnelier

Forme et fonction : Comment le design influence la performance

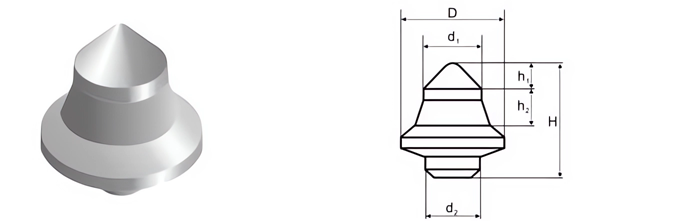

1. Boutons de rupture de la route :

- Caractéristiques : Ces boutons en carbure de tungstène présentent généralement une forme robuste, émoussée ou hémisphérique, conçue pour résister à des forces d'impact élevées.

- Avantages : Exceller dans le cassage et le concassage du béton, de l'asphalte et de la roche lors de projets de démolition et de construction de routes.

- Idéal pour : Marteaux hydrauliques, marteaux à percussion et autres équipements de démolition lourds.

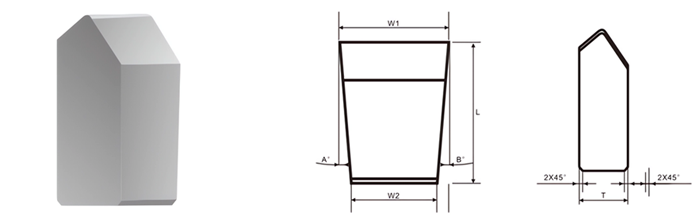

2. Boutons de perçage rotatif :

- Caractéristiques : Ces boutons en carbure de tungstène se présentent sous différentes formes, notamment conique, parabolique et en forme de ciseau, optimisées pour un forage efficace.

- Avantages : Ils offrent des vitesses de forage rapides et une formation précise des trous dans une gamme de matériaux, y compris la roche, le béton et l'asphalte.

- Idéal pour : Appareils de forage, machines de carottage et autres applications de forage rotatif.

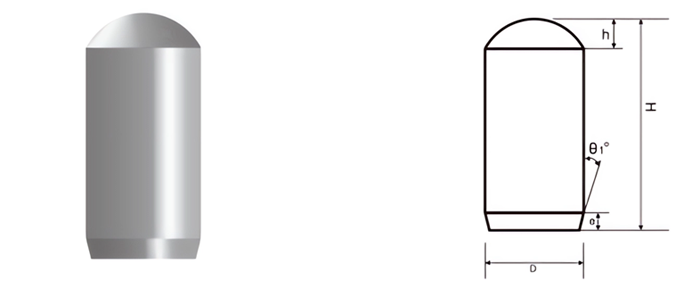

3. Boutons roulants :

- Caractéristiques : Ces boutons en carbure de tungstène présentent une surface lisse et sphérique conçue pour rouler et écraser.

- Avantages : Offrent une excellente résistance à l'usure dans les applications de broyage, de fraisage et de concassage des matériaux de construction.

- Idéal pour : Broyeurs à boulets, broyeurs à barres et autres équipements de traitement des matériaux.

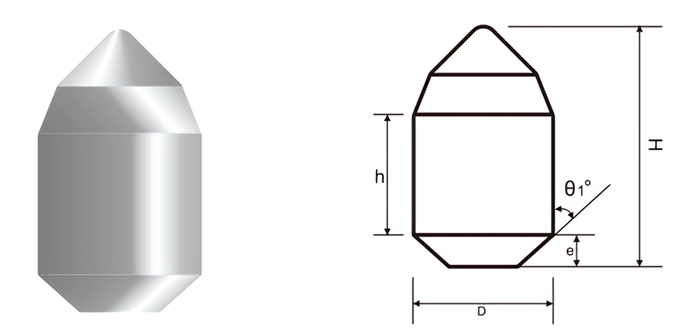

4. Boutons d'astuces TBM :

- Caractéristiques : Ces boutons en carbure de tungstène sont spécialement conçus pour être utilisés dans les tunneliers, qui présentent souvent des géométries et des arêtes de coupe complexes.

- Avantages : Ils offrent un équilibre entre la pénétration, la résistance à l'usure et la durabilité pour une excavation efficace des tunnels dans diverses conditions de sol.

- Idéal pour : Tunneliers utilisés dans les projets d'infrastructure, l'exploitation minière et d'autres applications de construction souterraine.

Spécifications techniques : Un regard comparatif sur les propriétés des boutons

De la composition aux normes : Points clés

| Fonctionnalité | Boutons de rupture de la route | Boutons de perçage rotatif | Boutons roulants | Boutons d'astuces TBM |

|---|---|---|---|---|

| Type | Rupture de route | Forage rotatif | Roulant | Conseils TBM |

| Composition | Carbure de tungstène (WC) avec liant de cobalt (Co) ou de nickel (Ni) | Carbure de tungstène (WC) avec liant de cobalt (Co) ou de nickel (Ni) | Carbure de tungstène (WC) avec liant de cobalt (Co) ou de nickel (Ni) | Carbure de tungstène (WC) avec liant de cobalt (Co) ou de nickel (Ni) |

| Dureté (HV30) | 1400 – 1800 | 1500 – 1900 | 1450 – 1850 | 1600 – 2000 |

| Résistance à la rupture transversale (N/mm²) | 1800 – 2500 | 1900 – 2600 | 1850 – 2550 | 2000 – 2800 |

| Résistance aux chocs | Excellent | Très bon | Bon | Excellent |

| Résistance à l'usure | Excellent pour les applications à fort impact | Très bon pour les applications de pénétration et de coupe | Bon équilibre entre la résistance à l'usure et à la pénétration | Excellent dans les environnements abrasifs et à haute pression |

| Tailles et formes | Différents diamètres et formes disponibles | Différents diamètres, angles de pointe et géométries disponibles | Différents diamètres disponibles | Formes et dimensions personnalisées en fonction de la conception du tunnelier |

| Niveaux et normes | Respecter les normes ISO, ASTM et autres normes industrielles pertinentes | Respecter les normes ISO, ASTM et autres normes industrielles pertinentes | Respecter les normes ISO, ASTM et autres normes industrielles pertinentes | Respecter les normes ISO, ASTM et autres normes industrielles pertinentes |

Applications dans la construction : Les points forts de chaque type de bouton

De la démolition au forage de tunnels : Une série de cas d'utilisation

- Démolition et construction de routes : Les boutons de brise-route sont essentiels pour briser les structures en béton, les revêtements en asphalte et les rochers lors des projets de démolition et de construction routière.

- Forage de fondation : Les boutons de forage rotatifs sont utilisés dans les installations de forage de fondations pour créer des trous pour les pieux, les piliers et d'autres éléments de fondation.

- Traitement des matériaux : Les boutons de laminage sont utilisés dans les broyeurs à billes et autres équipements de broyage pour concasser et traiter les agrégats, le ciment et d'autres matériaux de construction.

- Excavation de tunnels : Les boutons des tunneliers jouent un rôle essentiel dans l'excavation des tunnels pour les transports, la gestion de l'eau et d'autres projets d'infrastructure.

Analyse comparative : TRUER vs. les leaders de l'industrie

Naviguer sur le marché : Une comparaison côte à côte

| Fournisseur | Pays | Fourchette de prix (par pièce) | Spécialités |

|---|---|---|---|

| TRUER | Chine | $12 – $60+ | Solutions sur mesure, prototypage rapide, soutien exceptionnel à la clientèle |

| Élément six | ROYAUME-UNI | $18 – $75+ | Science des matériaux avancée, nuances de carbure haute performance pour les applications d'usure extrême |

| Kennametal | ÉTATS-UNIS | $15 – $65+ | Large gamme de boutons standard et personnalisés, vaste expérience dans l'industrie |

| Sandvik Coromant | Suède | $16 – $80+ | Solutions d'outillage innovantes, axées sur la durabilité et l'optimisation des performances |

Remarque : Les prix sont approximatifs et peuvent varier considérablement en fonction de la taille, de la géométrie, de la qualité, de la quantité et d'autres facteurs.Si vous souhaitez acheter des boutons en carbure abordables, résistants à la corrosion et durables, cliquez sur ici.

Avantages et limites : Peser le pour et le contre

Prendre des décisions éclairées : Une vision équilibrée de chaque type de bouton

| Type de bouton | Avantages | Limites |

|---|---|---|

| Rupture de route | - Résistance exceptionnelle aux chocs<br> - Efficace pour briser les matériaux durs comme le béton et la roche | - Ne convient pas au perçage ou à la coupe de précision<br> - Peut générer des bruits et des vibrations importants |

| Forage rotatif | - Des taux de forage rapides<br> - Formation précise des trous | - Peut s'user rapidement dans les formations extrêmement dures ou abrasives<br> - Le choix des boutons est essentiel pour une performance optimale |

| Roulant | - Excellente résistance à l'usure dans les applications de broyage et de concassage<br> - Contribuer à l'efficacité du traitement des matériaux | - Ne convient pas pour les applications de coupe ou de forage<br> - La taille et la dureté des boutons doivent être adaptées au matériau traité. |

| Conseils TBM | - Taux de pénétration élevés dans diverses conditions de sol<br> - Conçue pour un fonctionnement continu dans des environnements exigeants de creusement de tunnels | - Peut être coûteux en raison de la complexité des conceptions et des matériaux spécialisés<br> - Le remplacement des boutons peut prendre du temps |

Au-delà de l'essentiel : Facteurs influençant la performance et la longévité des boutons

Maximiser le retour sur investissement : Considérations clés

- Sélection des matériaux : Le choix de la bonne nuance de carbure est crucial, compte tenu de la dureté du matériau travaillé, des exigences en matière de résistance aux chocs et de l'usure abrasive potentielle.

- Attachement du bouton : Des techniques de brasage ou de soudage appropriées sont essentielles pour assurer une liaison solide entre le bouton et l'outil, évitant ainsi la perte prématurée du bouton.

- Conditions de fonctionnement : Des facteurs tels que la température, la pression et la présence d'eau ou d'autres fluides peuvent avoir un impact sur la performance et la durée de vie des boutons.

Pourquoi choisir TRUER ?

Votre partenaire en matière d'efficacité de la construction :

TRUER va au-delà de la fourniture de boutons en carbure de tungstène. Nous sommes votre partenaire dévoué dans l'optimisation des opérations de construction. Voici pourquoi les leaders de l'industrie choisissent TRUER :

- Une qualité sans compromis : Nous nous approvisionnons en carbure de tungstène de la plus haute qualité et appliquons des mesures rigoureuses de contrôle de la qualité tout au long de notre processus de fabrication.

- Expertise en matière de personnalisation : Notre équipe d'ingénieurs s'efforce de développer des solutions innovantes et personnalisées en matière de boutons en carbure de tungstène, adaptées à vos défis uniques dans le domaine de la construction.

- Prototypage et production rapides : Nous comprenons le rôle essentiel de la rapidité dans le secteur de la construction. Nos processus agiles nous permettent de livrer efficacement des prototypes et des séries de production.

- Un soutien exceptionnel à la clientèle : Nous sommes à vos côtés à chaque étape du processus, en vous fournissant des conseils techniques et une assistance d'experts pour garantir votre succès.

Foire aux questions : Répondre à vos questions sur les boutons de construction

1. Comment déterminer le type de bouton en carbure de tungstène le mieux adapté à mon application de construction spécifique ?

Le type de bouton en carbure de tungstène optimal dépend de facteurs tels que le matériau travaillé, le type d'équipement utilisé et l'équilibre souhaité entre la pénétration et la résistance à l'usure. Il est recommandé de consulter nos experts techniques pour obtenir des conseils personnalisés.

2. Quels sont les schémas d'usure typiques observés sur les différents types de boutons, et comment puis-je identifier le moment où un remplacement est nécessaire ?

Les schémas d'usure varient en fonction du type de bouton et des conditions d'utilisation. Les signes d'usure les plus courants sont l'aplatissement ou l'écaillage des boutons de démolition, l'émoussement ou la rupture des boutons de forage rotatif et l'érosion générale de la surface du bouton. Il est essentiel de procéder à des inspections régulières et de remplacer les boutons en fonction des limites d'usure établies.

3. TRUER peut-il fournir des boutons en carbure de tungstène avec des revêtements spécialisés pour une meilleure résistance à l'usure ou à la corrosion dans des environnements de construction exigeants ?

Oui, nous proposons une gamme de traitements de surface et de revêtements qui peuvent améliorer les performances et la longévité de nos boutons en carbure de tungstène en présence de matériaux abrasifs, d'agents corrosifs et d'autres conditions difficiles.

4. Quel est le délai de livraison habituel pour commander des boutons en carbure de tungstène personnalisés auprès de TRUER ?

Les délais d'exécution des commandes personnalisées varient en fonction de la complexité du dessin et de la quantité requise. Contactez notre équipe commerciale pour obtenir un devis personnalisé et une estimation des délais.

5. TRUER propose-t-il une assistance technique ou une formation sur site concernant l'utilisation et l'entretien de ses boutons en carbure de tungstène dans les applications de construction ?

Nous fournissons une assistance technique complète, y compris des consultations sur site, des programmes de formation et une assistance au dépannage, pour vous permettre de tirer le meilleur parti de nos produits et d'optimiser vos opérations de construction.