Introduction : A la conquête de l'impitoyable : Quand la durabilité rencontre la performance

Dans le domaine exigeant de la découpe des métaux, où les températures extrêmes et les matériaux abrasifs poussent les outils à leurs limites, seuls les plus résistants survivent. Entrer Carbure de type K brasé conseilsLes champions de l'industrie lourde sont conçus pour résister aux conditions de coupe les plus difficiles tout en offrant des performances et une durée de vie d'outil exceptionnelles.

Cet article se penche sur le monde des pointes brasées en carbure de type K, en explorant leurs attributs uniques, leurs avantages et les raisons pour lesquelles elles constituent le meilleur choix pour relever les défis d'usinage les plus difficiles.

Le défi des conditions de coupe extrêmes : Une bataille contre la chaleur et l'usure

Repousser les limites de l'usinage :

Certaines opérations d'usinage impliquent des conditions extrêmes qui peuvent rapidement dégrader les outils de coupe :

- Températures élevées : Générées dans la zone de coupe par le frottement et la formation de copeaux, les températures élevées peuvent ramollir les arêtes de coupe, ce qui entraîne une usure rapide de l'outil et une réduction de la précision.

- Matériaux abrasifs : L'usinage de matériaux abrasifs tels que la fonte, l'aluminium à haute teneur en silicium et les plastiques renforcés de fibres génère une usure importante des arêtes de coupe, ce qui réduit la durée de vie de l'outil et compromet l'état de surface.

- Coupes interrompues : Rencontrées lors de l'usinage de pièces présentant des formes irrégulières ou des surfaces interrompues, les coupes interrompues soumettent les outils de coupe à des charges d'impact et à des cycles thermiques, augmentant ainsi le risque d'écaillage et de fracture.

Pointes brasées au carbure de type K : Forgé pour la force et l'endurance

L'anatomie de la durabilité et de la performance :

Les pointes brasées en carbure de type K sont conçues pour résister aux rigueurs des conditions de coupe extrêmes et se distinguent par :

- Grades de carbure résistants : Les pointes de type K utilisent des nuances de carbure spécifiquement formulées pour une grande ténacité et une résistance à l'usure, à l'écaillage et à la rupture dans des conditions de température et d'abrasion extrêmes.

- Angles d'inclinaison positifs : Les angles de coupe positifs des pointes de type K réduisent les efforts de coupe et la production de chaleur, améliorant le flux des copeaux et prolongeant la durée de vie de l'outil dans les applications exigeantes.

- Joints brasés solides : Les pointes en carbure sont solidement brasées sur la tige de l'outil à l'aide d'alliages de brasage spécialisés qui résistent aux températures élevées et aux charges d'impact, garantissant l'intégrité de la pointe même dans les opérations les plus difficiles.

10 raisons pour lesquelles les pointes brasées en carbure de type K excellent dans les conditions extrêmes

Vaincre l'impitoyable avec confiance :

La construction robuste et les propriétés des matériaux des pointes brasées en carbure de type K se traduisent par plusieurs avantages clés :

- Résistance exceptionnelle à l'usure : Leurs nuances de carbure résistantes et leurs angles de coupe positifs minimisent l'usure due aux matériaux abrasifs et aux températures élevées, ce qui prolonge considérablement la durée de vie de l'outil.

- Dureté à chaud élevée : Les pointes de type K conservent leur dureté et l'intégrité de leur arête de coupe même à des températures élevées, ce qui garantit des performances et une précision constantes dans les applications exigeantes.

- Résistance à l'écaillage et à la fracture : Les nuances de carbure résistantes et les joints brasés solides permettent aux pointes de type K de supporter les charges d'impact et les cycles thermiques rencontrés dans les coupes interrompues.

- Amélioration du contrôle des puces : Les angles de coupe positifs favorisent un flux efficace des copeaux, réduisant l'accumulation de chaleur et empêchant le soudage des copeaux, qui peut endommager à la fois l'outil et la pièce à usiner.

- Forces de coupe réduites : Les angles de coupe positifs et les arêtes de coupe tranchantes minimisent les efforts de coupe, réduisant ainsi les contraintes sur l'outil, la machine-outil et la pièce à usiner.

- Finition de surface améliorée : Bien qu'elles ne soient pas conçues pour la finition, les pointes de type K permettent d'obtenir des finitions de surface étonnamment bonnes, en particulier dans les matériaux difficiles où d'autres géométries de pointes ont du mal à s'imposer.

- Polyvalence dans les applications exigeantes : Les pointes de type K conviennent à une large gamme d'opérations d'usinage lourdes, y compris l'ébauche, la semi-finition et la coupe interrompue dans des matériaux difficiles.

- Le rapport coût-efficacité dans des environnements difficiles : L'allongement de la durée de vie de l'outil et la réduction des temps d'arrêt offerts par les pointes de type K contribuent à une réduction globale des coûts, en particulier dans les applications où l'usure de l'outil est un problème majeur.

- Augmentation de la productivité : La capacité à supporter des vitesses de coupe et des avances plus élevées sans sacrifier la durée de vie de l'outil se traduit par une augmentation de la productivité et une réduction des temps de cycle.

- Réduction du risque de défaillance de l'outil : La construction robuste et les propriétés de résistance à l'usure des pointes de type K minimisent le risque de défaillance de l'outil, améliorant ainsi la fiabilité du processus et réduisant les taux de rebut.

Applications des pointes brasées en carbure de type K

La convergence de la durabilité et de la performance :

Les pointes brasées en carbure de type K sont le meilleur choix pour relever les défis d'usinage les plus difficiles :

- Usinage des aciers trempés : Leur grande dureté à chaud et leur résistance à l'usure les rendent idéales pour l'usinage des aciers trempés, qui sont notoirement difficiles pour les outils de coupe.

- Coupe de matériaux abrasifs : Les pointes de type K excellent dans l'usinage de matériaux abrasifs tels que la fonte, l'aluminium à haute teneur en silicium et les plastiques renforcés de fibres, où d'autres géométries de pointes s'usent rapidement.

- Opérations de coupe interrompues : Leur résistance à l'écaillage et à la rupture les rend bien adaptés aux opérations de coupe interrompue, telles que le fraisage de fentes, de poches et d'autres éléments de forme irrégulière.

Choisir la bonne pointe brasée en carbure de type K : Facteurs à prendre en compte

Optimisation de la sélection des outils pour les conditions extrêmes :

Le choix de la pointe brasée en carbure de type K optimale implique la prise en compte de plusieurs facteurs :

- Matériau de la pièce : La dureté, l'abrasivité et les propriétés thermiques du matériau sont des facteurs cruciaux pour déterminer la nuance de carbure et le revêtement appropriés.

- Conditions de coupe : La sévérité des conditions de coupe, y compris les vitesses de coupe, les avances, les profondeurs de coupe et la présence de coupes interrompues, influencent le choix de la pointe.

- Capacité des machines-outils : La rigidité et la puissance de la machine-outil peuvent avoir un impact sur les paramètres de coupe réalisables et sur la sélection de la taille et de la géométrie appropriées de la pointe.

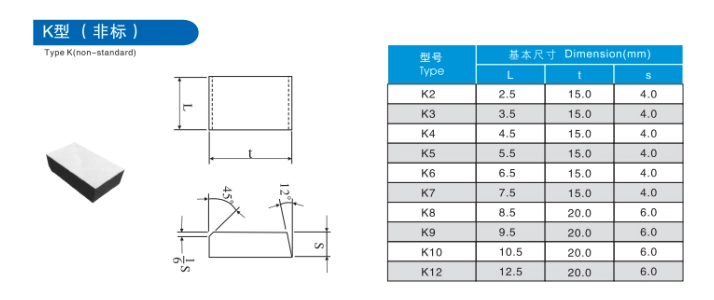

Sélection des pointes brasées en carbure de type K : Un guide simplifié

Pour faciliter le processus de sélection, voici un tableau résumant les applications typiques et les considérations pour les différentes géométries de pointes de type K :

| Type K Géométrie de l'embout | Applications typiques | Principales considérations |

|---|---|---|

| Insert carré avec angles d'inclinaison positifs | Ébauche polyvalente, fraisage intensif | Offre un bon équilibre entre la résistance et l'écoulement des copeaux pour une large gamme d'applications. |

| Insert triangulaire avec angles d'inclinaison positifs | Fraisage en plongée, ramping, usinage des angles | Offre une arête de coupe solide pour les opérations de coupe et de plongée agressives |

| Insert rond avec géométrie Chipbreaker | Coupe continue, améliorant le contrôle des copeaux | Permet un meilleur contrôle des copeaux et réduit les efforts de coupe dans les opérations de coupe en continu |

Questions fréquemment posées sur les pointes brasées en carbure de type K

Q1 : Peut-on utiliser le type K ? pointe brasée au carburepour les opérations de finition ?

A1 : Bien qu'elles soient principalement conçues pour l'ébauche et l'usinage intensif, les pointes de type K permettent d'obtenir des états de surface étonnamment bons dans des matériaux difficiles, là où d'autres géométries de pointes ont du mal à s'imposer. Cependant, pour obtenir un état de surface optimal, il est généralement recommandé d'utiliser des pointes spécialement conçues pour les opérations de finition.

Q2 : Quels sont les signes d'usure d'une pointe brasée en carbure de type K ?

A2 : Les signes d'usure les plus courants sont l'usure des flancs de l'arête de coupe, l'usure en cratère de la face de coupe et l'écaillage ou la rupture de l'arête de coupe. Dans des conditions de coupe extrêmes, l'usure peut se manifester par une perte de précision dimensionnelle, une détérioration de l'état de surface ou une augmentation des efforts de coupe.

Q3 : Comment puis-je maximiser la durée de vie de l'outil lorsque j'utilise une pointe brasée en carbure de type K ?

A3 : Les facteurs clés comprennent la sélection de la géométrie et de la nuance de pointe appropriées à l'application, l'optimisation des paramètres de coupe (en tenant compte de l'usinabilité du matériau et des capacités de la machine-outil), la garantie d'une application correcte du liquide de coupe et le maintien d'un réglage rigide de la machine.

Q4 : Quelle est la différence entre une pointe de type K à insertion carrée et une pointe de type K à insertion triangulaire ?

A4 : Les plaquettes carrées à angle de coupe positif offrent un bon équilibre entre la résistance et l'écoulement des copeaux pour l'ébauche générale et le fraisage intensif, tandis que les plaquettes triangulaires à angle de coupe positif offrent une arête de coupe solide pour les opérations de coupe agressive et de plongée en profondeur.

Q5 : Quand devrais-je choisir une pointe ronde de type K ?

A5 : Les plaquettes rondes à géométrie brise-copeaux sont souvent préférées pour les opérations de coupe en continu, car elles permettent un meilleur contrôle des copeaux et réduisent les efforts de coupe par rapport aux plaquettes carrées ou triangulaires.